MES

Manufacture

Data-driven operations/data-assisted decision-making/management to reduce costs and increase efficiency

Manufacture

MES Manufacture

Real-time, accurate and comprehensive collection of massive data

The advantages of MES manufacturing execution systems include improving production efficiency, achieving production collaboration, reducing production costs, improving product quality and enhancing production traceability. It can help enterprises achieve efficient, collaborative, and high-quality manufacturing management by optimizing production plans and resource utilization, monitoring and controlling production in real time, recording and storing detailed data during the production process.

Warehouse management

WMS Warehouse management

Better management of information, resources, actions, inventory and distribution operations.

As an advanced warehouse management system, WMS can improve accurate inventory management, reduce errors and losses, improve work efficiency, achieve resource optimization, and provide data analysis and reporting, among other advantages. It helps companies realize automation, efficiency and controllability of warehouse operations, improve supply chain management efficiency, reduce costs and enhance competitiveness.

Quality Control

QMS Quality Control

Assist enterprises to establish an effective quality assurance system to ensure institutionalization and standardization.

As a quality management system, QMS has the advantages of improving product quality, strengthening quality management, promoting continuous improvement, strengthening organizational operation efficiency, and enhancing market competitiveness. It helps organizations establish quality awareness, ensure the realization of quality requirements, and continuously improve and enhance quality levels, thereby achieving sustainable development and success of the organization.

Supplier relations

SRM Supplier relations

Comprehensive management of suppliers' supply capabilities, transaction records, and performance to optimize the supply chain and reduce procurement costs.

The SRM supplier relationship management system has the advantages of optimizing supply chain cooperation, improving supplier performance, reducing supply chain risks, providing innovation and cooperation opportunities, and reducing procurement costs. Help organizations establish good cooperative relationships with suppliers and enhance the stability and competitiveness of the supply chain.

Asset Management

EAM asset Management

Effectively manage equipment resources and maintain the normal operation of equipment.

The EAM asset management system is a comprehensive enterprise asset management solution that has the advantages of centrally managing asset data, optimizing maintenance plans, supporting procurement and decommissioning management, monitoring performance and optimization, and asset tracking and safety management. It helps organizations automate and optimize asset management, improve asset utilization, reduce operating costs, and ensure asset safety and reliability.

Manual work management is extensive, timeliness is slow, and data sources such as dispatch, process, personnel, and quality inspection are accurate.

When receiving the production task, will the warehouse materials be sufficient for production? If insufficient, will there be substitute materials?

There are many production orders, many personalized needs, many semi-finished products, difficult production scheduling, and difficult order delivery...

It is impossible to deal with inserting orders, urgent orders, supplementary orders, additional orders, and canceled orders. It is difficult to manage production line materials and difficult to manage

Professional service guarantee

7 * 24-hour hotline

Information consulting

Remote troubleshooting

On site technical support services

Suggestion: Improve the system

Operation: Report error exception

Impact: Partial system failure

Urgent: The system cannot operate

Working days 5*8 (9:00-18:00)

Remote, 4-hour on-site service

Holiday 4-hour response service

Provides 8-hour on-site service in the area

Acceptance confirmation

After implementation and delivery

Provide operation and maintenance reports

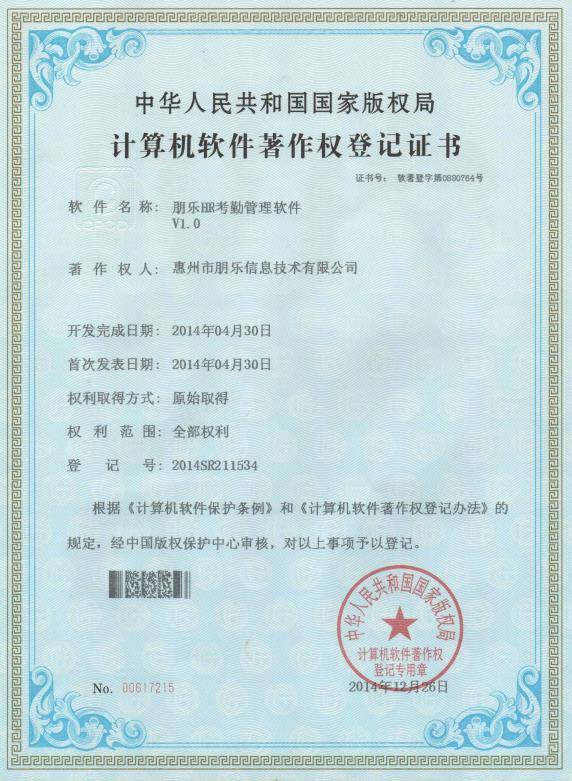

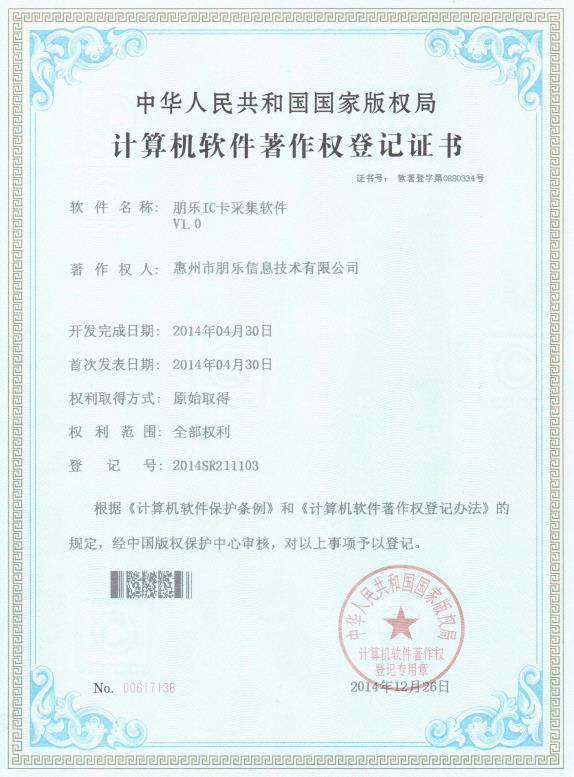

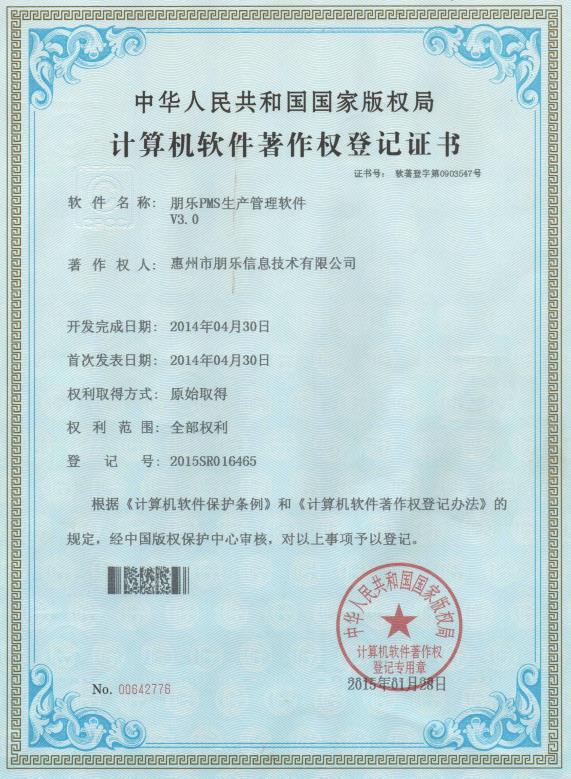

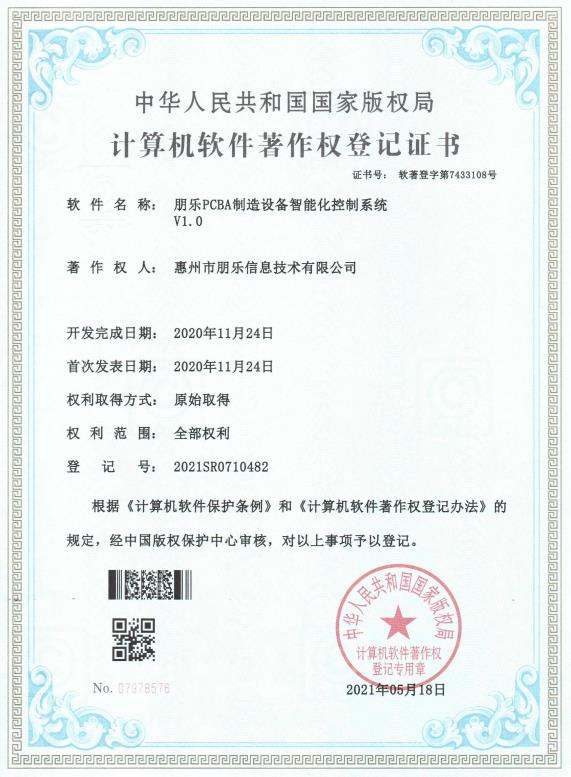

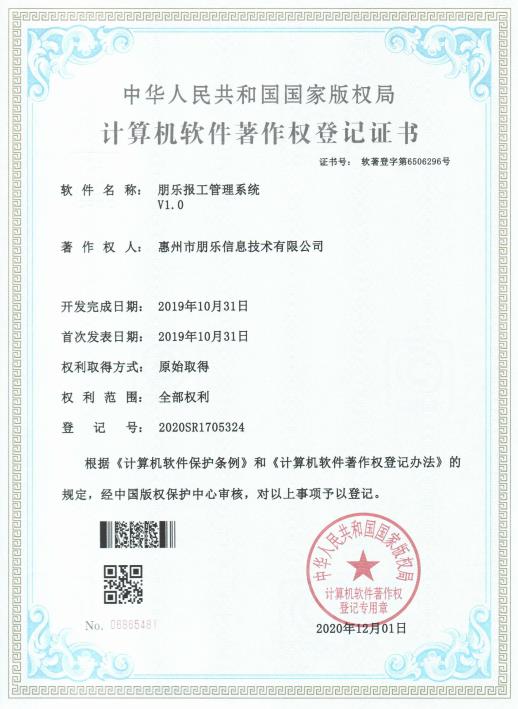

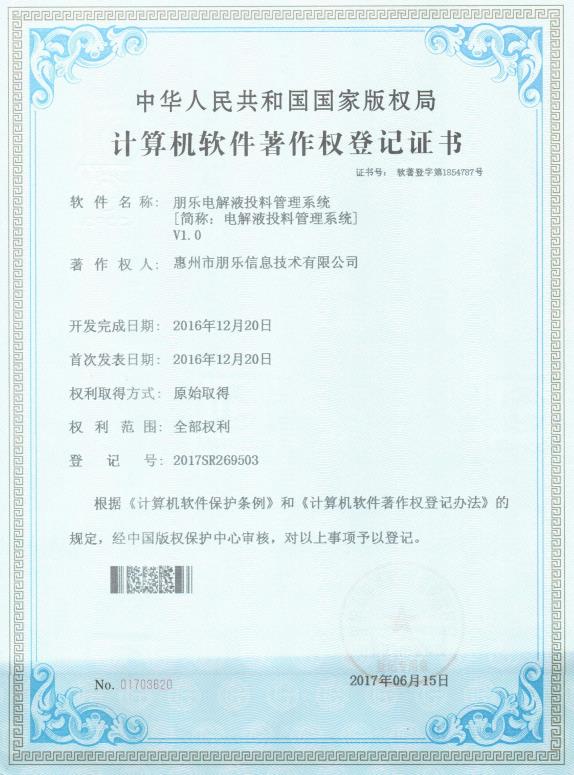

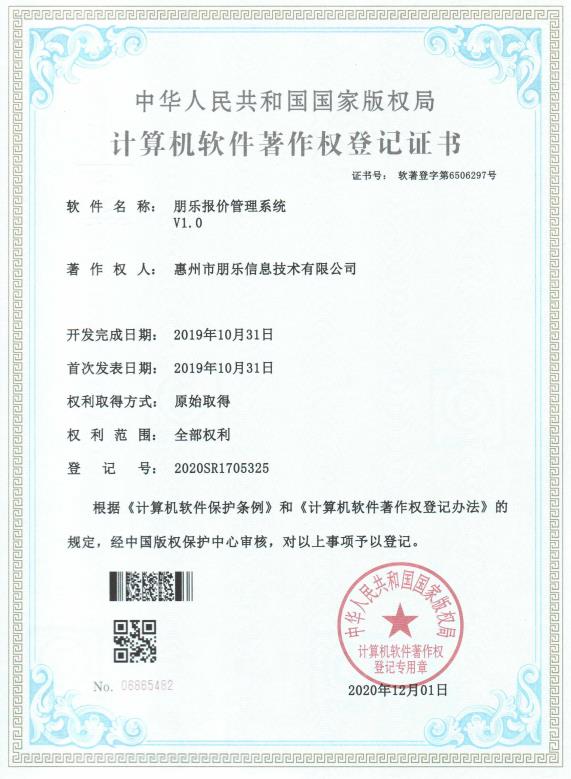

Company Honor

已成功提交

已成功提交